I. Boiler Automation

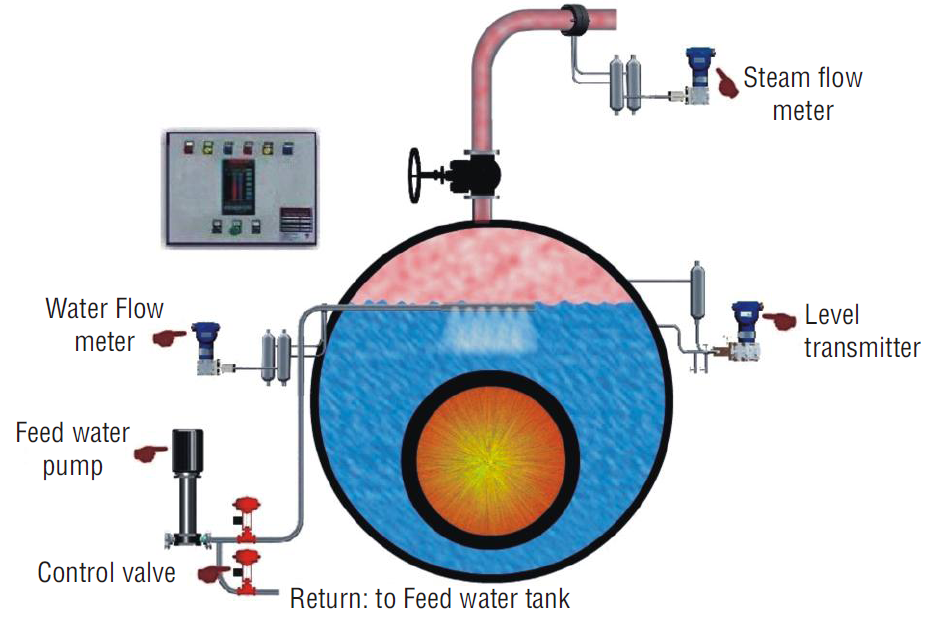

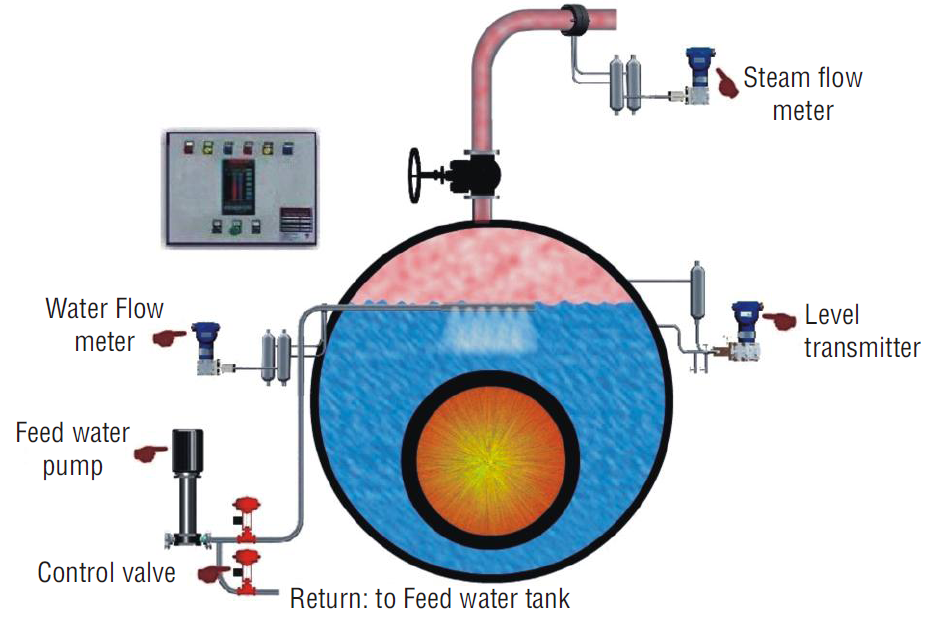

Thermax Automatic Drum Level Control System

Normally the water level inside the boiler is maintained by switching on-off of the feed water pump. This type of ON / OFF system has high degree of limitation in attaining sudden load fluctuation; it becomes further more complex when cold water is pumped in the boiler during surge load operation. To overcome such situation, automatic drum level control system has been proved to be a technically acceptable option to maintain a steady drum water level.

There are basically 3 types of drum level control systems in boilers.

Single element drum level control – throgh level transmitter.

Two element drum level control – thro level transmitter & steam flow

Three element drum level control – with level transmitter, steam flow & water flow

Key Features

Reduced variations in the steam pressure temperature, fuel firing rate.

Less boiler water carryover & consistent steam quality

Continuous operation of feed water pump

Combustion Control System

Maintaining the air fuel ratio at various loads in the boiler is the best way to maintain the boiler efficiency at optimum level. Combustion control systems are offered to control the fuel as per load and there after controlling the required primary air.

Key features

Improved combustion

Reduced Manual interventions

4 – 6 % Fuel saving by Air / Fuel ratio control

Conventional/PLC based control system is also available on request

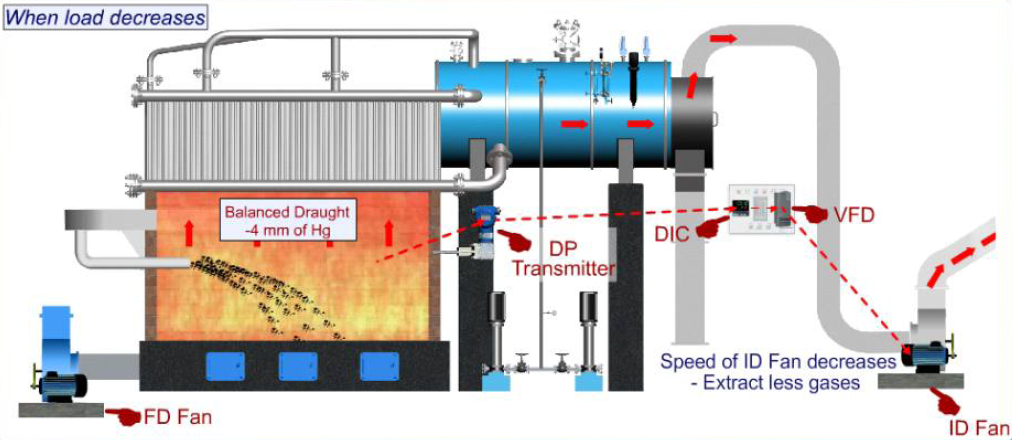

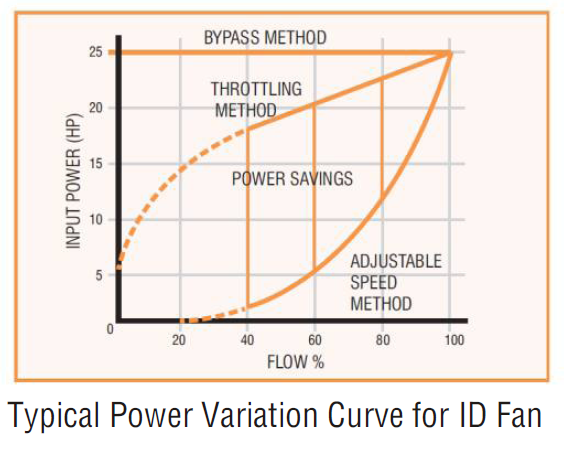

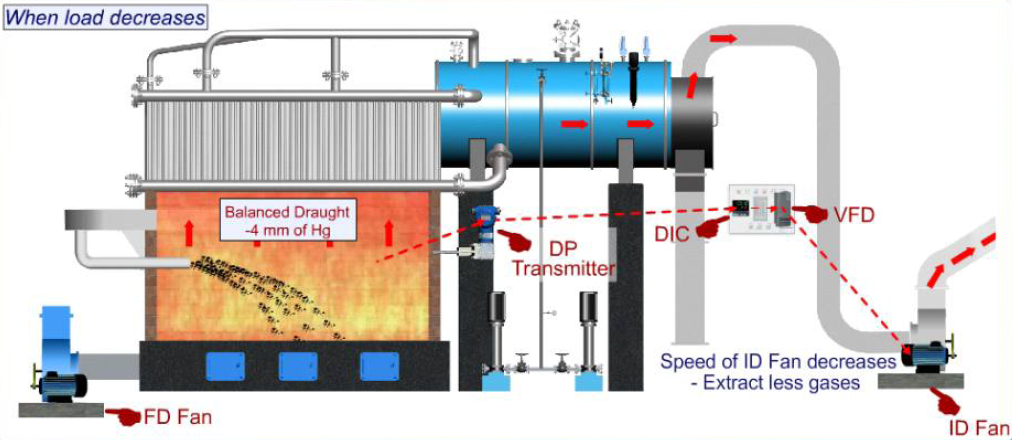

Furnace Draft Control System (Ecodraft)

Balanced draught system is considered as the most efficient draught system provided it is visualized and maintained to a predetermined value. A right draught helps to limit the ingress of excess air & at the same time avoid backfiring. Unfortunately this type of adjustment is repetative and needs accurate damper adjustment which humanly can never e achieved. Thus a draught control system can be introduced to maintain the preset draught inside the furnace. This system also helps in reducing the consumed load of the ID fan at part load and reduces particle carryover, thus decreasing the overall operational cost

Key features

- 100% safety against back firing

- Reduced Manual interventions

- Optimized heat transmitter through Boiler Automation

- Up to 40 % Power saving by Furnace draught control system

II. Waste Heat Recovery Solutions

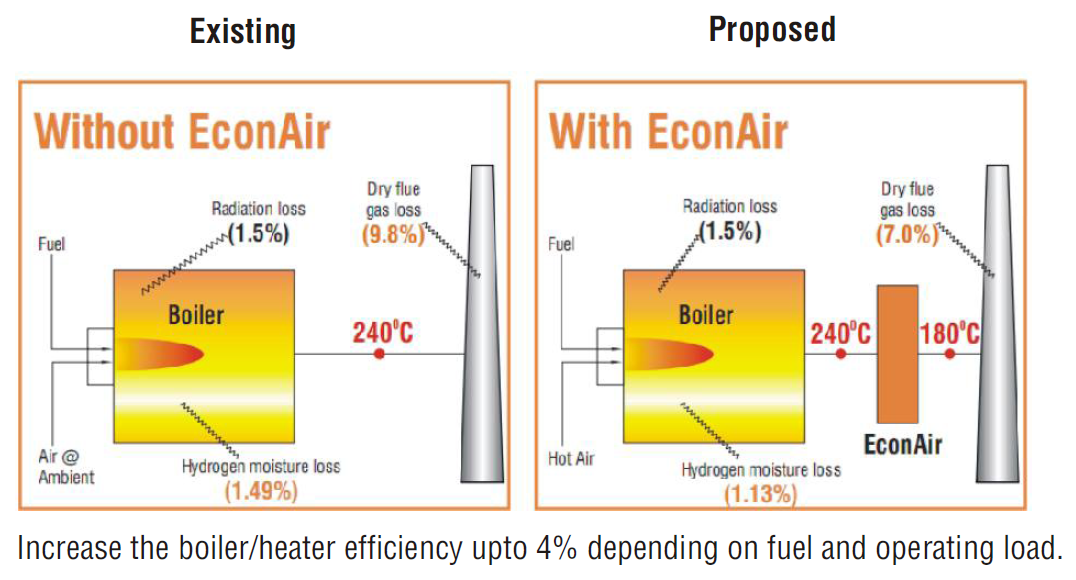

EconAir – Air Pre Heater for Solid, Oil & Gas fired Boiler & Heater

Dry flue gas losses form close to 75 –80% of total losses of any oil/gas fired boilers/heater. Reducing stack temperature can reduce the losses. Air pre heater is a simple gas to gas heat exchanger, where flue gas is used to preheat the combustion air, thereby reducing the stack temperature.

Features and benefits

- Reduction in dry flue gas losses resulting in fuel saving

- Better quality of combustion increases overall performance

- Both counter cross flow and parallel flow designs are available

- Ease of spot cleaning of tube surface

Applications

- Thermic fluid heaters (Oil and gas fired)

- Steam boilers (Oil and gas fired)

HydroMax – Water Preheater for Solid Fuel Fired Boilers

Features

Ease of maintenance

No IRB formalities required

Simple and compact design

Increased feed water temperature

Increase the thermal efficiency of the boiler to the tune of 3-4% depending operating load.

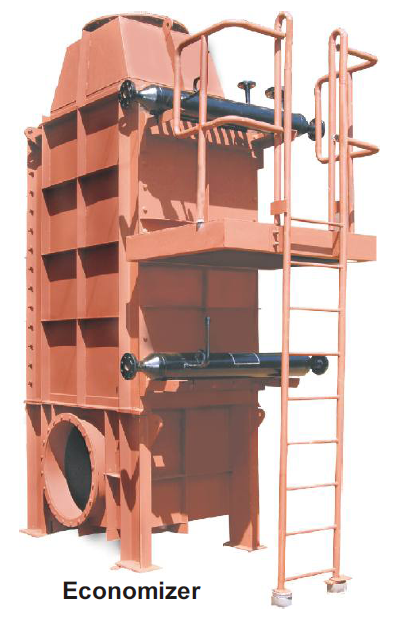

Economizers – Oil, Gas & Solid Fuel Fired Utilities

Economizers perform a key function in providing high overall boiler thermal efficiency by recovering the energy from the flue gas before it is exhausted to the atmosphere.

Economizers are basically tubular heat transfer surfaces used to preheat boiler feed water before it enters the steam drum.

Key features

- Fuel saving up to 5%

- Higher optimum efficiency can be ensured by using CI gills

To avoid corrosion due to sulphuric acid condensation, CI gills are used to protect metal tubes.

- This is proven technology mainly used to recover heat from the exhaust gas of furnace oil fired systems.

We can offer various types of economizers including CI gilled, MS Finned, etc.

Waste Heat Recovery for Activated Carbon Industry

In activated carbon plant the flue gases generated from the process are vented out to atmosphere at around 400-600 Deg C. However steam is required for there process. Hence separate oil fired boiler is used for this purpose. We can propose the waste heat recovery boiler which can be designed for optimum heat recovery from waste flue gases and thus customer can save fuel as well as space.

Waste Heat Recovery from Incinerator Exhaust

High temperature gases produced from incinerator is passed through the smoke tube heat exchanger. This heat can be utilized to generate the following:

Hot water

Saturated steam

Heating thermal oil

Process/ Engine Heat Recovery Solutions

Incinerator Heat recovery Solutions

Kiln/ furnaces/Engine exhaust gas heat recovery solutions

Possible Heat recovery in the form of Steam/Hot water/Thermal Oil

Optimum design to suit customer requirements

Prominent installation base

100% market share in Activated Carbon Industry for process Heat recovery

Attractive Paybacks

Turnkey solutions available

We can also offer any other customized waste heat recovery solutions including radiators etc.

III Efficiency/ Capacity Enhancment Solutions

Turbulent air flow, counter to the feed of fuel, gives higher residence time and enables complete combustion when fuel is in suspension, thus ensuring a higher efficiency.

We can offer the FluidCon technology up gradation solutions for all type of existing solid fuel fired smaller capacity units with stationery grate arrangement for fuels like husk, coal, baggasse, etc.

Features

Saving of fuel up to 4%

Reduce excess air thereby lowering O2 level.

Less maintenance, no frequent raking of bed required.

Due to very good turbulence in the furnace, best combustion quality is assured.

Nozzles designed by CFD ensure good combustion

IV De-aerators (Process & Boiler Application)

Purpose of De-aerator

To remove oxygen, carbon dioxide and other non condensable gases from feed water.

To heat the incoming makeup water and return condensate to an optimum temperature.

Minimizing solubility of the undesirable gases.

Providing the highest temperature water for injection to the boiler.

Improve heat transfer in boiler

Utilize low pressure exhaust and flash steam

Common collection points for high & low temperature condensate returns

Economizing of overall operation with strong reduction in the chemical treatment costs.

Key Features

- Guaranteed Oxygen removal Up to 7 PPB

- Designed confirming to IBR/ASME

- Prominent Installation base

- Turnkey solutions available

- Highest process deareator installed capacity: 250 m /hr ,171 Deg.C

- Conventional/PLC based control system available

Type of Deaerator

- Process De-aerator-Tyre industry

- Boiler Deaerator-Boiler feed water application

Range

- Flow – upto 300 m /hr

Temp – 200 C

- Flow – upto 50 m /hr

Temp – 105 C

V. Fuel Shift (Oil to Solid)

We can convert existing oil fired boiler system to solid fuel fired boiler by adding necessary combustor arrangement suiting to the proposed fuel. We can do the conversion by either providing external fired combustors or by converting the existing combustion chamber by integral grate bar arrangement based on various parameters like site conditions, boiler model, process steam requirement etc. By providing external fired combustor the capacity de-ration is limited up to 40%, depending upon the boiler model.

Key features

Attractive payback

Designed to provide maximum possible output

Ensured Safety and life of original pressure parts

Customized/ turnkey solutions can be worked out with heat recovery units.

Grate/Chain Grate/Bubbling bed combustor designs available based on capacity and fuel.

VI. Hot Gas Generator

Hot gas generators are used in many industrial applications where hot gases are required for various processes. Hot Gas Generator (HGG) consists of Atmospheric Fluidised Bed Combustor (AFBC) designed for burning the coal. Flue gases generated are taken to the process through ID fan. Dilution air is provided by damper after combustor.

Key Features

Proven AFBC type of design

Turnkey solutions available

Successful installation base

Capacity up to 20 mkcal/hr available

Customized design to suit the process requirements

Application

Cement Industry

Any other process industries requiring hot gases

VII. Process Waste Utilisation Solutions

We can offer the following process waste utilization solutions:

Pet coke

Sawdust

Spent earth

Blast Furnace Gas

Bio gas firing system

Coke Breeze from steel plant

Thermax has expertise in burning 130 fuels eg. Coal, wood, husk, lignite, bagasse,various agro-waste, petrol, kerosene, Light Diesel Oil, High Speed Diesel, Furnace Oil,Natural Gas, LPG, Hydrogen, etc.

We can offer any customized solution for upgradation, modernization,efficiency improvement for boilers & heaters in process heat industries.