Menu

- Home

- Thermax Products

- Products

- Steam Boiler

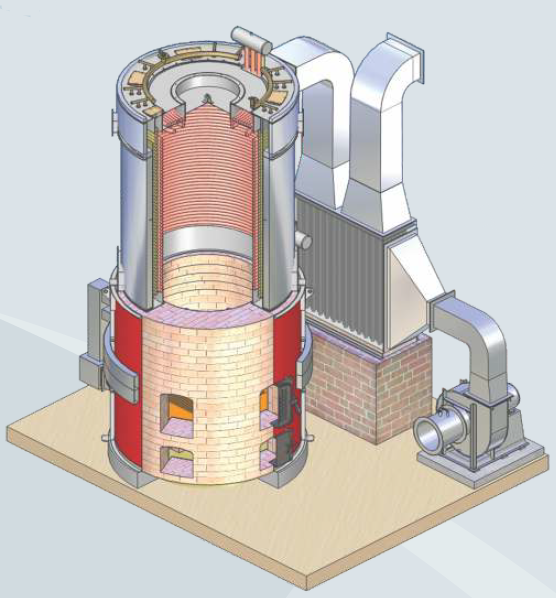

- Thermic Fluid Heater

- Hot Water Generator

- Hot Air Generator

- Steam Accessories

- Special Products

- Air Compressor

- Air Cooled Reciprocating Oil Lubricated Air Compressor

- Air Cooled Reciprocating, 100% Oil Free & Seize Free Air Compressor

- Air Cooled Reciprocating High Pressure Air Compressor

- Air Cooled 100% Oil Free Scroll Air Compressor

- Air Cooled Oil Lubricated Screw Compressor

- Air Cooled Rotary type, Oil Free Claw Compressor

- Air Cooled Wobble type Oil Free Air Compressor

- Vacuum Pump

- Services

- News

- Contact

Or call us now +91 7798985580

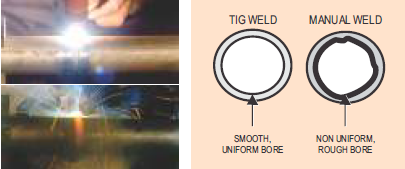

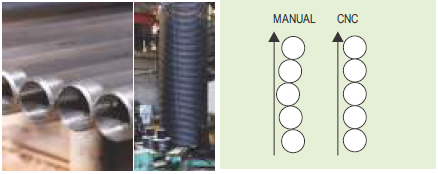

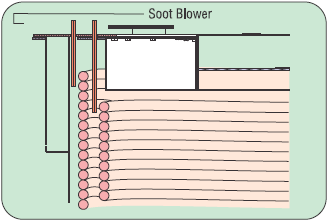

clean and maintain uniform heat transfer. This reduces variation in sufficiency when compared with the effect of manual cleaning in conventional thermal oil heaters.

clean and maintain uniform heat transfer. This reduces variation in sufficiency when compared with the effect of manual cleaning in conventional thermal oil heaters.