The best of safety, reliability, operational ease - all at an affordable cost

Safety

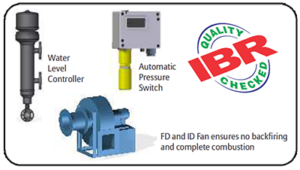

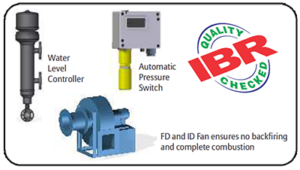

- Steam generation and feed water with automatic controls thus reducing dependence on manual operation

- Balance draft system with forced draft and induced draft fan ensures no back firing and complete combustion

- Designed as per Indian Boiler Regulations

- Stringent standards adopted for quality checks and testing, as per Indian Boiler Regulations

Reliability

- Superior components checked against stringent quality norms as per ISO 9001 certification e.g. feed water pump with SS internals

- Robust triplex grate bar in combustor for high reliability

- High usable heat to process – 97% steam dryness

- Manufactured with state-of-the-art quality standards to ensure long lasting operation

Easy to operate

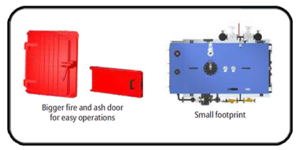

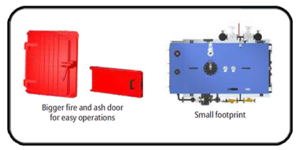

- Large access ports for fuel charging and ash removal designed to reduce operator fatigue

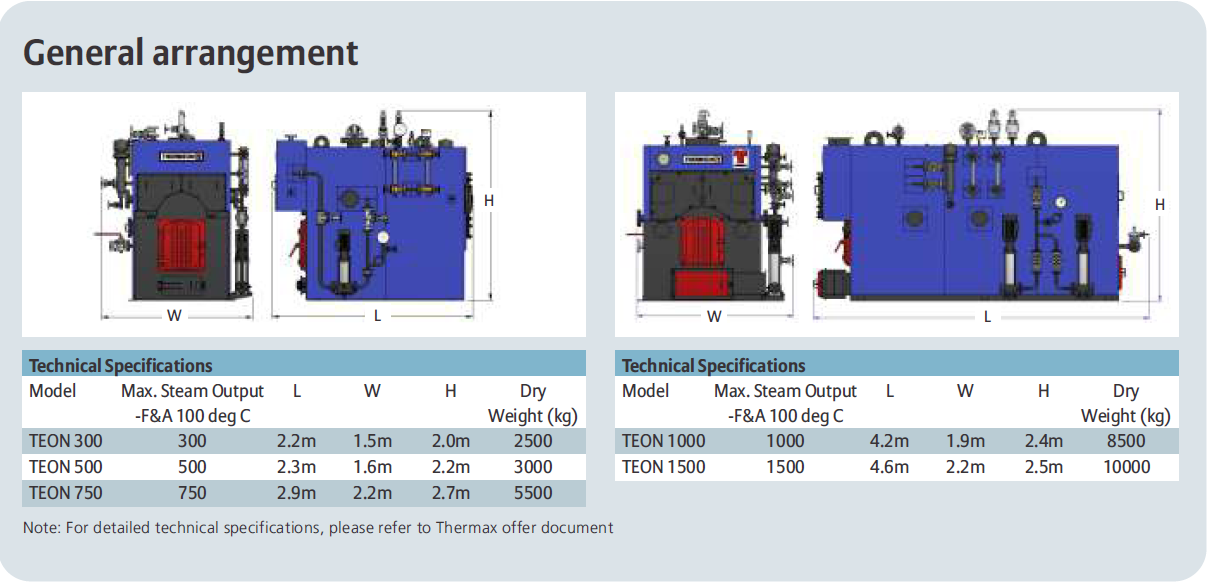

- Compact design results in very small footprint and saves on installation space

- Low height of boiler allows easy access to all parts and controls

Affordable

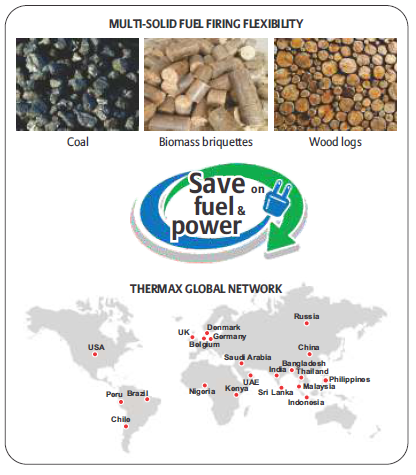

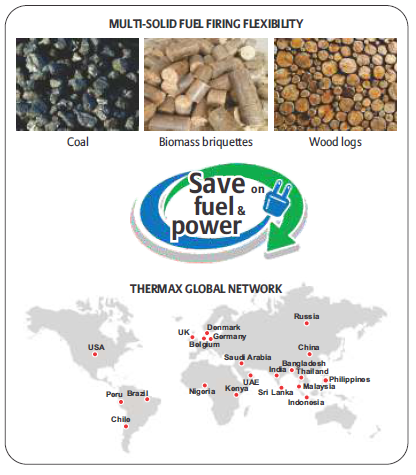

- Suitable for coal, wood, biomass briquettes

- Ideal replacement for oil fired boiler – saves on fuel and power costs

- Boiler supplied as package along with assembled components, pre-insulated, and with a good sense of aesthetics

- Minimal site work for installation

- Thermax operations are backed by a large network of subsidiaries, sales & service offices around the world

THERMEON multi solid fuel fired steam boiler- ideal for a multitude of industry applications

Food Processing

- Steaming process in cashew nut manufacturing

- In jaggery preparation for sugar juice concentration

- Milk pasteurization

- Steam heating for sweet preparation using milk products

- Mango pulp processing

- Steam heating process in noodles and pasta manufacturing

- Steam for syrup heating in confectionery/ candy manufacturing

- Fruit juice beverage manufacturing

- Instant quick food – fish processing

- Masala / spice manufacturing

Textiles

Textiles

- Yarn sizing

- Garment washing and drying

Chemicals

Chemicals

- Steam heating in jacketed vessel

- Drying

Hotels, Hospitals and Institutions

Hotels, Hospitals and Institutions

- Steam for power laundry, kitchen, hot water

Pharmaceuticals

Pharmaceuticals

- Formulation, ayurvedic drug manufacturing

Packaging

Packaging

- Heating in corrugated box manufacturing

Coir and Mattresses

Coir and Mattresses

Leather curing

Leather curing

Textiles

Textiles Chemicals

Chemicals Hotels, Hospitals and Institutions

Hotels, Hospitals and Institutions Pharmaceuticals

Pharmaceuticals Packaging

Packaging Coir and Mattresses

Coir and Mattresses Leather curing

Leather curing